We all know water is the safest, most efficient, and generally easiest fluid to work with in HVAC systems. Water has the highest sensible heat transfer properties of any of the reasonable fluid choices. It does require attention and proper maintenance to ensure it works to design throughout the life of the system. A system feeder will help the operator keep the system fluid efficient.

Here are three distinct benefits of hydronic system feed units:

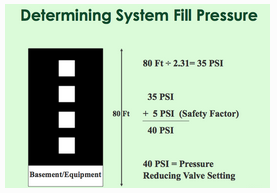

1. Maintain system pressure

The System Feed Unit will monitor the system pressure and add more fluid to maintain the pressure setting. The units have alarms to monitor low and high pressure readings, always keeping the system at the optimum operating pressure and protecting the heat transfer equipment.

2. Maintain glycol concentration for the system

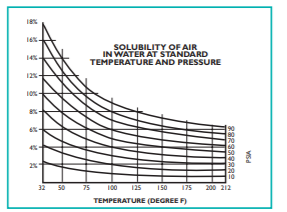

Adding glycol has multiple benefits for a closed-loop hydronics system. The glycol will give the owner peace of mind, knowing that the system will not freeze up and fail during the cold periods of the year.

Consulting engineers put a lot of time and effort into determining and selecting equipment to handle the heating loads on their systems. They go through multiple calculation iterations to determine how the equipment will derate due to the glycol concentration. That concentration must be maintained to ensure the built system performs as the design intended. The feeder unit can store the exact premixed glycol concentration and inject it as required into the loop.

3. Isolation from a continuous make-up water system

In the event of a system leak, a typical backflow preventor based make-up water assembly will just continually add water to the system - feeding the leak. System feed units store a limited amount of make-up system fluid in a tank with a low water limit. An audible alarm will sound when the water level gets below the low limit. No additional water will be put into the system during that condition. That alarm gives the building team an early signal letting them know there’s an issue that needs to be addressed.

A system feed unit is an integral part in the safe, efficient operation of any hydronics system. Keep the system running at peak performance.

If you’re looking for helping with size, selection and set-up for a system feed for your applications, let us know!

Submit a Comment