The wasted energy from the US industrial sector is enough power to run 22 cities the size of New York City.

What if there were a way to harness this wasted energy and convert it into usable energy? Fortunately, there are a number of technologies commercially available for waste heat recovery. Unfortunately, much of what is currently available is not economically feasible for most industrial applications.

In order to recover waste heat, three things are needed:

- An accessible source of waste heat

- Recovery technology

- A use for the recovered energy

If you have the accessible source of waste heat and a use for the recovered energy, all you then need is the recovery technology. Much of the industrial waste heat is in the low-temperature range (100-400°F).

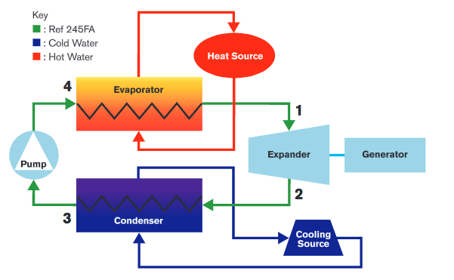

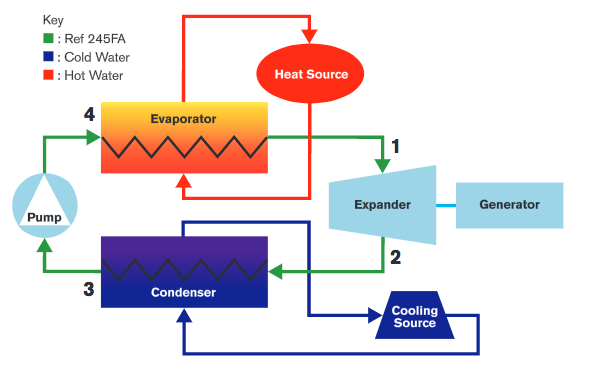

One technology available for this type of waste heat recovery is organic rankine cycle (ORC) technology. This technology uses low to medium temperature waste-heat sources and converts the thermal energy into electricity. Industrial applications such as petroleum, ceramic, chemical, geothermal, food and beverage, power generation and waste disposal all can produce appropriate amounts and temperatures of waste heat to drive an organic rankine cycle.

The ORC technology uses conventional HVAC components, is self-powered and works with low-temp heat sources (>170°F water, >400°F gas). Additionally, maintains good efficiency at partial load, has around a two- to seven-year payback and is, perhaps most notably, a green system with a negative carbon footprint!

The ORC technology uses conventional HVAC components, is self-powered and works with low-temp heat sources (>170°F water, >400°F gas). Additionally, maintains good efficiency at partial load, has around a two- to seven-year payback and is, perhaps most notably, a green system with a negative carbon footprint!

Currently available ORC modules can generate 35kW to 6MW of power from heat sources. A scroll expander can generate from 1kW to 30kW. A screw expander generates anywhere from 35kW to 1MW and a turbine expander generates from 100kW to 6MW.

Installing an ORC module can help you realize clean, renewable power with no carbon footprint, no toxic emissions, a quick return on investment and excellent system efficiencies.

Are you looking to recapture waste energy in your industrial application? Dig deep into ORC technology to see if it makes sense.

Submit a Comment