You may find a scruffy old-timer still out there who longs for the old days when equipment in mechanical rooms was a mass of gurgling, lurching, belt-driven noise. But today, most equipment technicians and engineers prefer the sleek hum of equipment with reduced voltage starters, variable frequency drives and, most recently, Bluetooth connectivity to the Internet. These days, mechanical rooms more closely resemble the polished deck of the Starship Enterprise over the lackluster metal of a turn-of-the-century factory.

You may find a scruffy old-timer still out there who longs for the old days when equipment in mechanical rooms was a mass of gurgling, lurching, belt-driven noise. But today, most equipment technicians and engineers prefer the sleek hum of equipment with reduced voltage starters, variable frequency drives and, most recently, Bluetooth connectivity to the Internet. These days, mechanical rooms more closely resemble the polished deck of the Starship Enterprise over the lackluster metal of a turn-of-the-century factory.

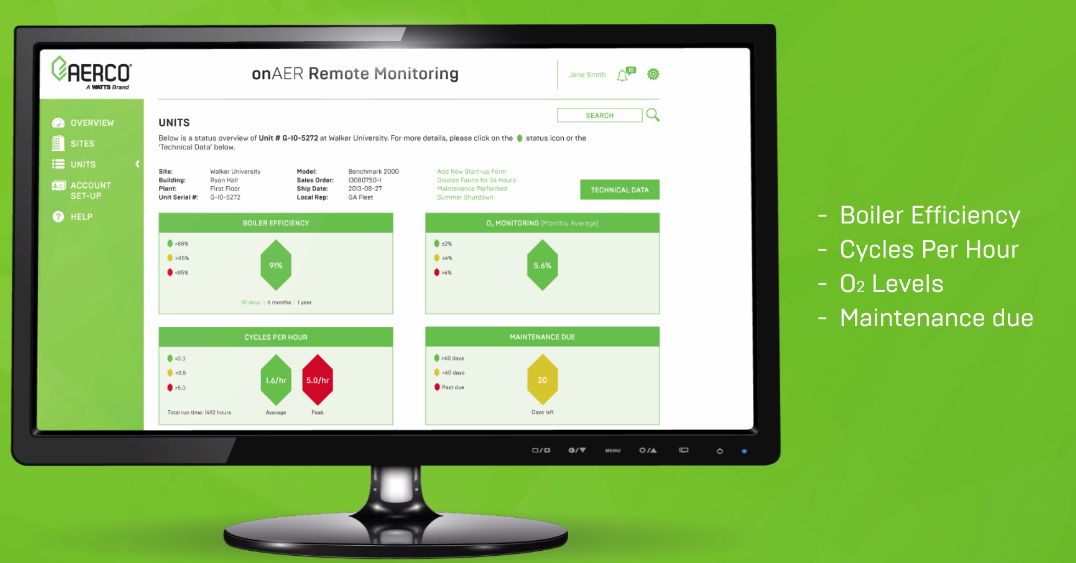

HVAC equipment is now outfitted with intelligent systems that send information about the equipment’s operation into the cloud. The data can then be analyzed and sent to building owners with information about the health of the system in addition to pro-active performance recommendations.

How can this connectivity help building owners, facility managers, specifying engineers and mechanical and service contractors?

Equipment rooms are now populated by machines that were once fully mechanical but that are now connected to send and receive data over a network. Some naysayers grumble that all this innovation just gives maintenance staff and contractors something else to fix when it breaks. However, the technology is so smart and so sophisticated that the benefits far outweigh any potential concerns.

For example, HVAC equipment that taps into the power of the Internet can:

- Proactively adjust to building and occupant needs

- Warn building owners when problems will occur

- Alert when it’s time for maintenance

- Provide updates on any changes in energy usage.

Is this technology any different from traditional building management systems?

The answer to this is complex. Building management systems (BMS) or building automation systems (BAS) have been centralizing the control of building HVAC, lighting and other systems for years. These systems are connected via controllers and provide data from equipment sensors regarding temperatures, power usage and more. However, historically this data has been vastly underutilized.

The new intelligent HVAC systems provide a bit more than traditional BMS/BAS. In addition to offering controls, the newer equipment offers analytics transmitted to the cloud. As more and more HVAC equipment becomes “smarter,” this data will be integrated for maximum efficiency across the entire system.

How will building owners and maintenance staff handle this massive influx of data?

Intelligent HVAC systems will become more complex as time goes by with huge amounts of data. Apps that manage the data with a smooth user-friendly interface will be imperative. Additionally, having the data go to expert HVAC service contractors in addition to your on-site maintenance team may be helpful for some building owners. Service technicians who are certified in the operation and maintenance of specific equipment adds yet another layer of protection to ensure the system runs as efficiently as possible.

The beauty of intelligent HVAC systems is that your team will no longer troubleshoot problems after they arise. Rather, they will be well-informed about overall system health and will move from a troubleshooting mindset to a preventative maintenance mindset. Additionally, increased knowledge will increase accountability, allowing for better decision making on every level of your building’s operations.

Wise design engineers and building owners will review intelligent HVAC equipment now to stay ahead of the curve in commercial building design and operation. The future is happening now.

If you're interested in HVAC equipment available with this technology now, click below to see a short video example of how AERCO's new Benchmark Platinum condensing boiler offers enhanced functionality in addition to onAER remote technology with internet connectivity.

Submit a Comment