Observations from the field at an assisted living facility.

(The purpose of this blog series is to provide real-world examples of hydronic HVAC and plumbing issues observed in the field, our recommendations, and, when feasible, the ultimate outcome. The names of those involved are omitted to protect the innocent. Some photos include blatant mistakes or oversights. Viewer discretion is advised.)

Last week, I visited an assisted living facility in North Carolina to help a contractor set up a VFD on a self-sensing vertical inline pump. The facility utilized a water-source heat pump HVAC system that had been in operation for a number of years. The system included an open cooling tower, a plate & frame heat exchanger, two atmospheric gas-fired boilers, two boiler pumps, one system pump, and condenser water pump. The owner requested the contractor install this additional pump both for backup of the existing condenser water pump and to potentially improve cooling capacity since the owner said the system had been underperforming for some time.

Set-up and programming of the new self-sensing condenser water pump went without a hitch. Based on the application, the pump was set for constant flow mode. However, operation at the design flow of 370-GPM was not possible due to excessive system pressure drop, and the pump was left to operate at 150-GPM until the contractor remedies the other issues in the system.

Excessive pressure drop in the condenser water loop is a result of two primary factors:

- Heat exchanger is partially clogged. Dirt buildup within the plates is causing a tremendous amount of restriction to flow, cutting cooling capacity.

- Observation: When we tried to observe the pressure drop across the HX, we observed the pressure gauge pipes to be completely clogged. It was evident that the HX has been cleaned before since one of the plate retaining bolts was left loose (see photo), but it has not been cleaned for some time.

- Recommendation: Remove the HX plates for pressure washing and thorough cleaning. Have plenty of spare gaskets on hand. Also, add a sediment separator device to the condenser water loop to prolong maintenance intervals and equipment life. Unfortunately, this will require a full HVAC system shut down.

- New piping for the backup condenser water pump was sized for pump connection size, creating additional pressure drop.

- Observation: System pipe size is 5”. Pump connection size is 2.5”. Manufacturers base pump connection sizes on pump performance criteria alone. Pressure drop per hundred feet and velocity should be considered when sizing system piping. In this case, the 2.5” pipe adds an extra 30-ft of head for the new pump to overcome.

- Recommendation: Replace the 2.5” piping with 5” pipe to reduce system pressure drop.

When these two items are addressed, the new backup condenser water pump should be able to operate a full system flow with no issues.

Other observations, unrelated to the purpose of our visit, are as follows:

- The condenser water pump (both existing and new) frequently loses prime. This is because the open tower loop piping extends overhead to exit the mechanical room, creating an inverted “U” in the piping. Without re-piping to keep the entire pipe low or some form of make-up water in the top of that piping, keeping that line full of water will be a challenge throughout the life of the system. This is a condenser water piping “no-no!"

- Notice all the fan belts hanging on the loose heat exchanger bolt? Those are for the belt-driven fan in the cooling tower. These would not be necessary with a direct-drive fan.

- There is only one system pump and one condenser water pump. If either of these goes down, the entire building HVAC system goes down. This is unwise for any building design, much less an assisted living facility. (At least now they have a backup on the condenser water loop.)

- The base-mounted end suction pumps for the system and condenser water loops are incorrectly installed. It isn’t a matter of IF these pumps will fail, but WHEN. (See previous blog Top 5 Most Common Installation Mistakes on Base Mounted Pumps for more background.) Observed installation mistakes include:

- Bases not bolted to house-keeping pad

- Bases not grouted

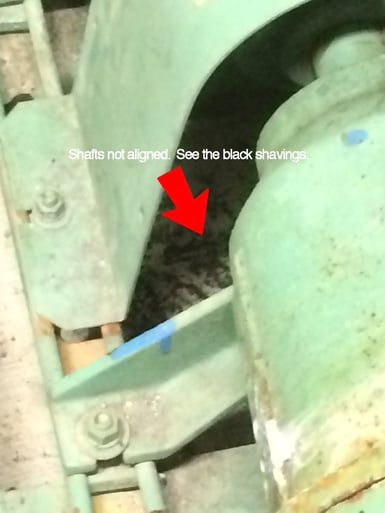

- Shafts not aligned (see black coupling shavings in the photo below)

- No suction diffuser support

- Flex connectors squashed

- Seal flush line not installed

- Gauges improperly installed

- Worker uses the pump motor as a footstool. Not only is this unsafe for the worker, but it has a negative impact on the shaft alignment. (Thank goodness is was turned OFF at the time!)

For us, these mistakes are glaring because this is our profession and we know what to look for. Sadly, this is an all too common scenario in mechanical rooms everywhere. The good news is, where there is a problem, there is an opportunity for a solution! Ask your local rep to walk through your mechanical room, and find out what opportunities await. Having your doctor find an illness early on is much better than waiting until it is too late.

Submit a Comment