Pumps are serious business in the world of commercial building. Engineers spend vast numbers of hours reviewing usage requirements so that the correct pumps are specified, purchased and installed for building and system needs. However, you may hear months, or even years, later that the building owner is experiencing problems with that same pump you painstakingly selected.

Pumps are serious business in the world of commercial building. Engineers spend vast numbers of hours reviewing usage requirements so that the correct pumps are specified, purchased and installed for building and system needs. However, you may hear months, or even years, later that the building owner is experiencing problems with that same pump you painstakingly selected.

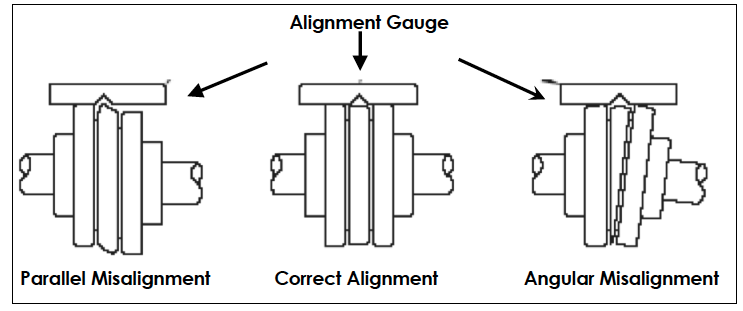

Here’s a little nugget of engineering truth: you can select the absolute perfect pump for an application, but if the pump isn’t installed and aligned correctly, that pump will never run properly and will almost certainly fail before it should. Base mounted flexible coupled pumps MUST be aligned properly prior to running. (Side note: If you never want to worry about pump alignment, you can always choose a vertical inline pump!) Review this checklist of things you need to pass along to the installing contractor and to the building owner to be sure that base mounted flexible couple pumps are installed and aligned correctly to avoid costly and inconvenient down time and repairs:

A straight-edge alignment should be done to the pump and motor shafts prior to tightening the pump base to the housekeeping pad.

- Pump base should be leveled on the housekeeping pad prior to tightening the bolts and grouting.

- Prior to final alignment, the pump flange bolts should be removed to demonstrate no pipe weight is transmitted to the pump housing, then reattached.

- Final alignment should be performed after the system and the pump/motor have reached normal operating temperature.

- Use a laser alignment tool for the most accurate alignment results.

- A printed report from the laser alignment tool should be presented to the owner and reflect alignments have been completed within the following tolerances:

- Parallel: 0.002”

- Vertical: 0.002”

- *Angular: 0.0017 / 1” (*most critical)

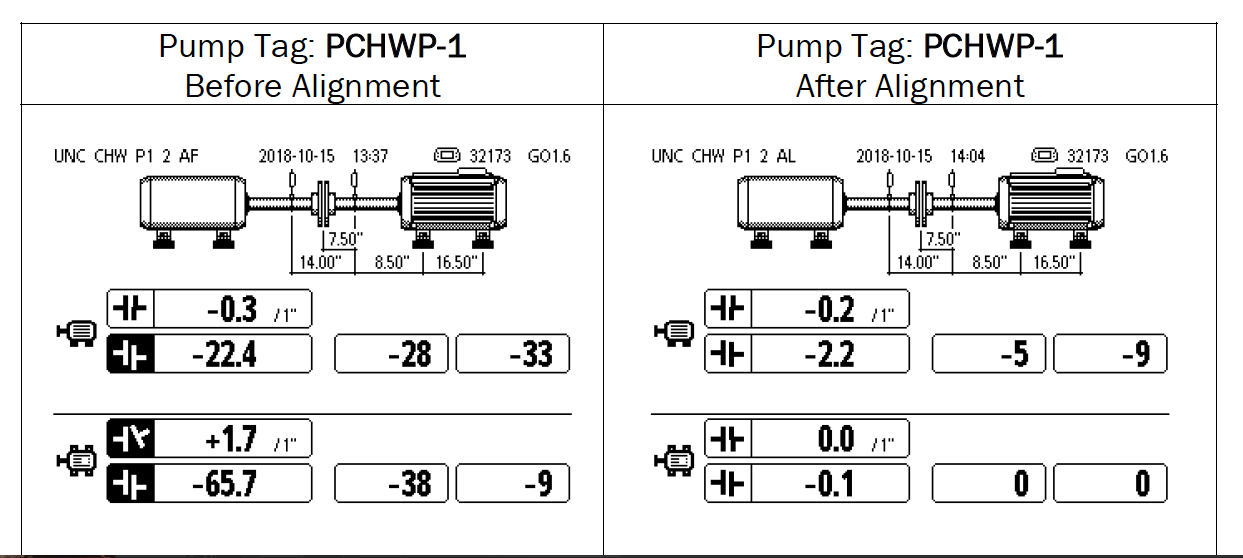

This is an example of a laser alignment printout. You can see the Before and After numbers. In the After boxes, the numbers from top to bottom mean:

- Side Angular: 0.0002 / 1”

- Vertical: 0.0022”

- Overhead Angular: 0.000 / 1”

- Parallel: 0.0001”

The numbers to the right are recommended adjustment numbers to get to 0.0”, but those greatly depend on the accuracy of the instrument placement.

With proper installation, alignment and maintenance, the pumps you select today should be humming along for many years into the future.

.png)

Submit a Comment