In a perfect world, pumps would never leak and motors would run forever. However, in reality mechanical seals eventually stop sealing and motors stop motoring. For now, let’s only focus on mechanical seals and an effective fix which may help extend the life of a pumps’ mechanical seal.

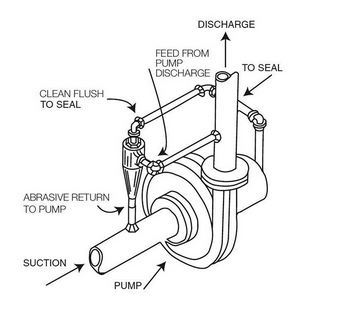

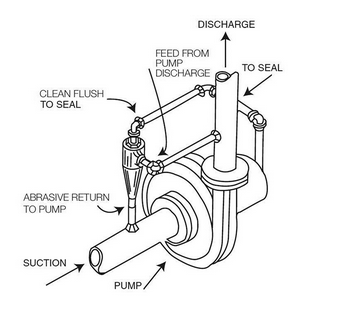

Keeping the area between the mating faces of a mechanical seal clean and free of debris is vital towards mechanical seal performance, improving seal life and reducing maintenance costs. Adding a cyclone abrasive separator to the seal flush line on your can do just that by ensuring a “clean flush."

Liquids in your HVAC system can contain many abrasive particulates that can easily cause irreparable damage to seal faces rather quickly. This is especially true with aging systems which may have become “dirty” over time. A quick test to see if your system is “dirty” is to take a water sample into a clear container. If after a few minutes debris settles on the bottom of the container, you may be compromising your mechanical seals. The debris you see at the bottom is being pumped to the faces on your mechanical seals.

Cyclone separators also have a place in newly constructed HVAC systems. Inevitably, foreign particles will be introduced during the construction process – think metal grindings, sand, dust particles, etc. Adding this simple design element to your new install will help prevent premature seal failure after start-up.

It’s important to note that a cyclone abrasive separator does not remove any particulates from your system nor will it clean a “dirty system:" it only ensures a “clean flush” of your mechanical seals.

Installing a cyclone abrasive separator on a new project or adding as a retrofit to an existing pump is quick and simple. The picture below depicts a typical install.

Contact your local representative to learn more about ways to improve seal life by adding cyclonic abrasive separators to your system.

Blog image and reference source for this post are from this article from Pumps & Systems magazine.

.png)

Submit a Comment