Hydronic HVAC systems use water to transport energy throughout a building for the purposes of occupant comfort. Once the system is initially filled, except for occasional leaks or losses during equipment maintenance, that original water stays within the piping system and is re-circulated and reused continually. Typically, the water is fed to the building from the municipality system, and, depending on the water chemistry, some chemical treatment may be required. But with EVERY hydronic system, the system fill pressure must be set and the air must be purged. To do this, you need the following components:

Hydronic HVAC systems use water to transport energy throughout a building for the purposes of occupant comfort. Once the system is initially filled, except for occasional leaks or losses during equipment maintenance, that original water stays within the piping system and is re-circulated and reused continually. Typically, the water is fed to the building from the municipality system, and, depending on the water chemistry, some chemical treatment may be required. But with EVERY hydronic system, the system fill pressure must be set and the air must be purged. To do this, you need the following components:

- Air Vents: Automatic and manual, these should be installed at the air separator and at every high point in the piping system. Check out TACO Comfort Vents and MetraFlex Vents.

- Air Separator: Install at the lowest pressure point of the system, usually on the suction side of the system pumps. Check out TACO Comfort air separators.

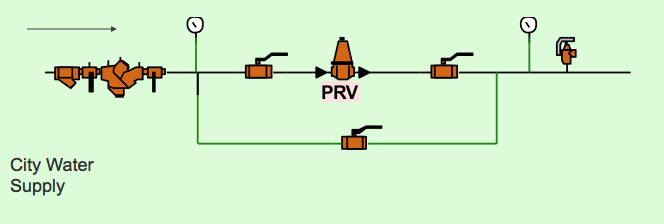

- Make-Up Water (MUW) Assembly: The link between the hydronic system and the domestic water feed. The MUW

assembly includes a Pressure Reducing Valve (PRV), a Pressure Relief Valve, and full size bypass piping for use during initial system fill. Usually connects to the hydronic system at the air separator inlet (lowest pressure point and remove air as quickly as possible). We sell prefabricated MUW Assemblies, made by our Pump'nFlo team.

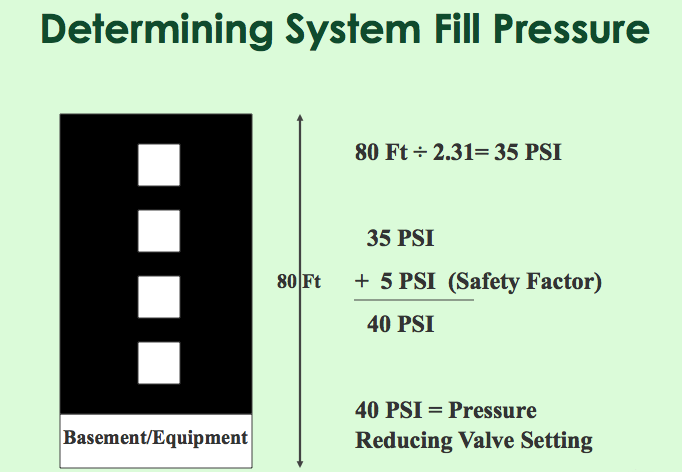

assembly includes a Pressure Reducing Valve (PRV), a Pressure Relief Valve, and full size bypass piping for use during initial system fill. Usually connects to the hydronic system at the air separator inlet (lowest pressure point and remove air as quickly as possible). We sell prefabricated MUW Assemblies, made by our Pump'nFlo team. - Pressure Reducing Valve (PRV): Mentioned above as part of the MUW assembly, the PRV must be set to a pressure that ensures 5-psig of positive pressure at the top of the system. This keeps the system full of water, purges out the air, and ensures the pumps have a constant pressure at their suction.

Air in a hydronic system is bad news because 1) dissolved air in the water will corrode/rust any piping or equipment made of ferrous materials and 2) free air within the piping will prevent flow, either partially or fully. Air lock within a piping system can stop flow as effectively as a closed valve. Dissolved air also hinders the heat transfer properties of water!

A common mistake we see, especially on variable speed (VFD) pumping systems, is increasing the pump speed to ensure flow at the highest point in the system. (Keep in mind, the “highest point” does not necessarily mean the “farthest point.") In one example, there was an air handling unit (AHU) on the roof of a three-story school building, located above the mechanical room. The contractor increased the pump speed to force water through the starved coil, but it did not work. The AHU still had insufficient flow, and the VFD began “hunting” (oscillating speeds). The reason it did not work was the PRV in the first floor mechanical room was set to 12-psig. For this three-story building, the vertical height to the AHU on the roof was 40-feet. So, 17.3-psig was needed to get water to the top of the system. Another 5-psig was added to ensure positive air purge pressure. The PRV setting was adjusted to 23-psig and the flow issue at the AHU disappeared.

HVAC pumps are typically meant to circulate and not boost water. So, if you are having flow issues at the top of your hydronic system, make sure the PRV has been set appropriately. Proper PRV settings at the MUW assembly, a good air separator, and venting at piping high points will help ensure proper flow and operation of your hydronic HVAC system. As always, if you need help determining what equipment you need to properly run your system, please contact your local manufacturer's representative for engineering assistance.

.png)

Submit a Comment