According to an article in Flow Control, up to 50% of the costs from breakdowns of rotating machinery are directly related to misalignment. A misaligned pump shaft happens when the two shafts are not running on the same axis through the center. Pumps should be correctly aligned not only horizontally but vertically as well. If you have an accurately aligned pump shaft, you can most likely prevent multiple breakdowns as well as significantly reduce pump down time.

According to an article in Flow Control, up to 50% of the costs from breakdowns of rotating machinery are directly related to misalignment. A misaligned pump shaft happens when the two shafts are not running on the same axis through the center. Pumps should be correctly aligned not only horizontally but vertically as well. If you have an accurately aligned pump shaft, you can most likely prevent multiple breakdowns as well as significantly reduce pump down time.

Misaligned pump shafts lead to problems. And problems lead to down time. You can reduce the likelihood of pump down time and avoid these common issues:

- Premature bearing seal, coupling and shaft failures

- Looseness of foundation bolts and base-plates

- High vibration and temperatures

- High power consumption

- High maintenance costs

Methods of pump alignment

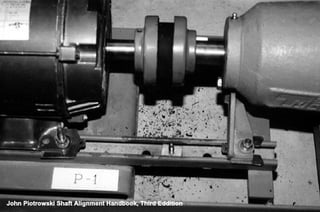

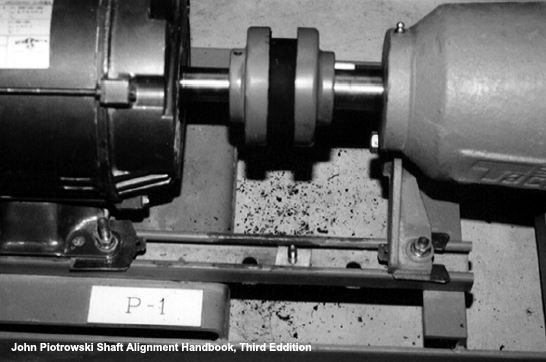

There are traditional methods of pump alignment still in use, including straightedges and dial gauges. Both methods leave something to be desired. Straightedge (or ruler) alignment tends to be quick and fairly easy but it is dependent on the vision of the operator and doesn’t produce the precise results required by today’s machinery. Dials offer a higher degree of accuracy over straightedge alignment but they require a much more skilled technician and the process is time-consuming.

The latest, fastest, and most accurate, method of pump alignment is laser pump alignment.

Benefits of laser pump alignment

Laser shaft alignment offers a number of advantages, including:

- Laser beams are not affected by vision, gravity or bracket sag.

- Most laser shaft tools have software to calculate highly accurate values for both horizontal and vertical corrections.

- Some laser alignment systems have programs that will measure and correct other shaft alignment issues, such as soft foot, bolt bound or base bound conditions.

- You can store the corrected alignment values digitally for maintenance records.

These are only a few of the benefits that laser pump alignment can offer. Consider scheduling a laser pump alignment for your facility to ensure that your pumps are properly aligned and reduce pump down time and your long-term maintenance costs.

-png.png)

Submit a Comment